Plastic welding

What exactly is the plastic welding process?

Polymers have a much lower melting point than steel or aluminum. This means that less energy is needed to achieve a permanent bond between the parts being welded. As with other metal welding processes, it is of course necessary to use a welding wire for modules or containers.

The interaction of heat and pressure permanently bonds and completely fuses the polymer molecules of the materials being joined. As a result, the parts of the workpiece are inseparably joined.

When and where is polymer welding used?

Polymer welding is of great importance in the manufacture of tanks. Wherever factory machine welding is not possible, welding is used. This method ensures high productivity with consistent precision and the highest welding quality.

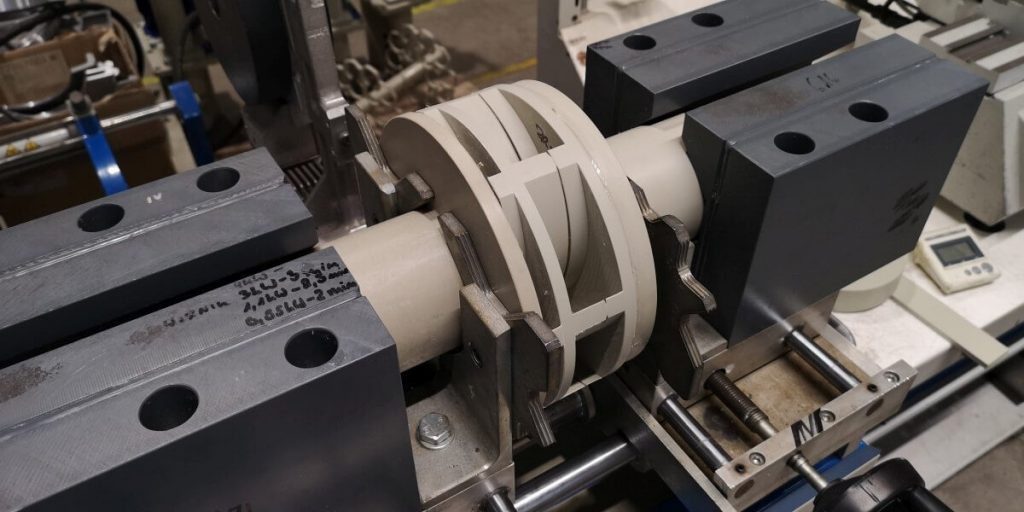

Of course, permanent joining of plastic parts is also realized for smaller products, e.g. welding of pipes, pump and filter.

What are the main principles of welding plastics?

Preparation of the surface

Qualification of welders

The welders at KKS are all trained and regularly inspected and certified by TÜV - Süd in order to meet the highest requirements.

Welding temperature

It happens that some polymers have a very fast plasticization but are not yet weldable. For others, it can be difficult to maintain a slightly excessive melting temperature throughout the weld.

Both too low and too high temperatures are unsuitable for welding polymers. In the first case, the weld will break; in the second, material continuity will be broken and strength will be compromised.

Insufficient joining force and uneven heating of the materials.

The last two points refer to the applied force and the uniform heating of all surfaces. Even very good heating of components may not be sufficient if areas to be bonded are joined with too little force.

On the other hand, heating only one area will result in a poor bond because not all materials will be plasticized.