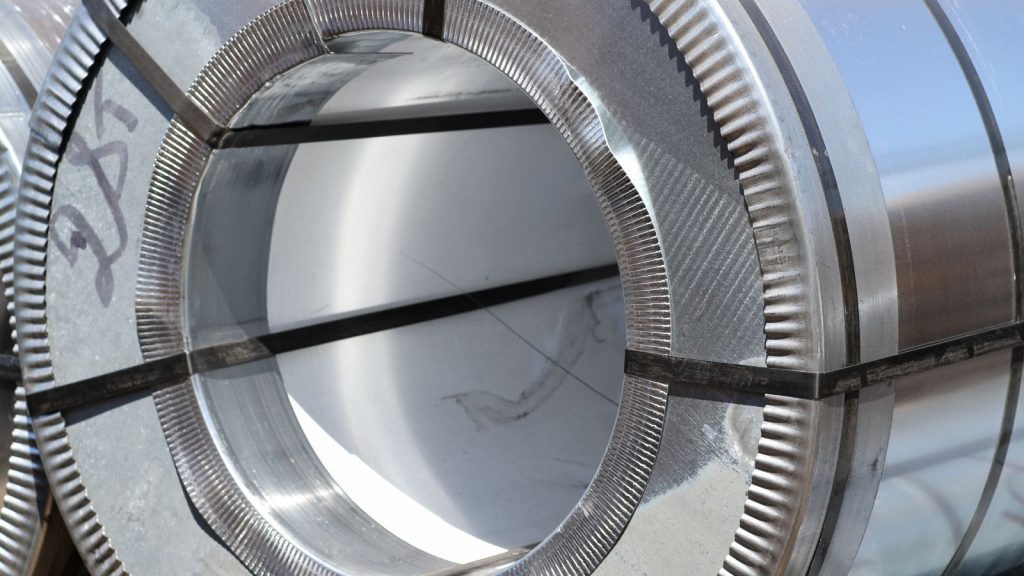

Electroplating

Electroplating is intended to protect the product from corrosion damage. It also protects the surface from mechanical damage and increases the aesthetic level of the object. At KK SOLUTIONS we understand the electroplating of base materials, plastics and metals. Motivated by advanced projects, we rely on the expertise of our employees to support excellent quality galvanized.

What is the process of electroplating?

Electroplating is the process of creating a perfectly adherent metallic coating for the component made of another material. In this process, the base material is immersed in an electrochemical bath. During this process, a thin metallic layer (usually chrome or copper) is formed on the surface, which protects the product and improves its aesthetic properties.

The technological process of producing an electroplated coating can be divided into two phases:

- chemical

- electrolytic

Stages of electroplating

During chemical processing, the surface of the workpiece is prepared for coating with a conductive material. Workpieces are not perfectly smooth and also have some irregularities. The molded part is subjected to the following processes:

- Etching

- Neutralization

- Activation/sensitization

- Plating process

Only after the above chemical processes can the second step, electrochemical application of the electroplated coating, take place. In this step, the surface of the product is enriched with a metallic coating, which is the final top layer. They can be made of copper, chrome, brass, nickel, gold or silver. At KK SOLUTIONS we understand the complex electroplating processes.

Advantages of Electroplating?

The goal of KK SOLUTIONS is to become a business partner of electroplating companies. We know how important it is to offer customers what they expect from a product used to be used in further applications. Plastics have the advantage over their metal counterparts in that they are lighter, easier to process and have high strength. The process of their production and processing is also much simpler compared to metal products.

The process of electroplating itself serves several purposes. One is to improve the electrical properties of the object. This is achieved by coating the article with a thin layer of metal. The second reason has to do with increasing the resistance of the product to mechanical influences. Plastics can have high hardness and low abrasion or impact resistance. Therefore, an electroplated metal coating provides additional reinforcement of the surface and the entire casting or molded part.

Another advantage of electroplating plastics is that a uniform protective layer is achieved. No other method can reach the smallest nooks and corners of a product so effectively to coat it with the desired metal. At the same time, the cost of electroplating is not high, which favors the spread and development of this method of protecting objects.

Electroplating is also important for the aesthetics of objects. It is carried out for products in the fields of cosmetics, beauty, household appliances and electronics, automotive or medical. In each of these cases, function, aesthetics and accuracy are important and that is what we understand.

KK SOLUTIONS is your partner in business!

At our manufacturing facility in Lubañ, we produce the most complex plastic products used in the plating process. We also offer our partners access to the best production machinery used in machine parks for the production of plastic parts.

If you are looking for the right business partner to provide your company with the best technological solutions, contact KK SOLUTIONS today!