PVC Polyvinyl Chloride

PVC called polyvinyl chloride, is one of the most important polymers in the manufacturing industry. Without it, a myriad of industries - from medical to construction - would have huge problems creating the most necessary products. Knowing the market demand for PVC products, KK SOLUTIONS offers its customers products designed from PVC, as well as the processing of this material.

What is PVC and what properties does it have?

The polymerization of vinyl chloride produces polyvinyl chloride, or PVC (PVC). This is a synthetic polymer that is used to make plastics. Along with PP, PVDF and PE, PVC is one of the most widely used polymers. Why is it so popular in the market? Polyvinyl chloride is cheap to produce, resistant to the effects of water, acids, alkalis, does not yield to pressure, but at the same time is easy to process, provides an insulating barrier and does not emit harmful compounds.

How is polyvinyl chloride produced?

The polymerization of vinyl chloride can take place in one of three ways. These are as follows:

- suspension polymerization (also called pearl or microblock polymerization) - the process produces individual PVC fragments in the form of tiny beads.

- emulsion polymerization - pH-stabilizing aids are added in the reaction medium. Under the influence of this process, latex, or liquid polymer, is formed, from which at a further stage polyvinyl chloride can be produced.

- block (or bulk) polymerization - in this case, an initiator is added directly to the monomer. This produces a solid block of polymer, which can be granulated or left in its original state.

Applications of polyvinyl chloride in industry

It is impossible to list all possible applications of polyvinyl chloride. It is used in the following industries:

- Construction industry - PVC is an indispensable raw material for water pipes, air ducts and electrical cables. It is also used as a construction product, for example, for erecting partition walls or creating window and door frames. Polyvinyl chloride is also an excellent insulator, so it can be used as a soundproofing, thermal insulation or waterproofing product.

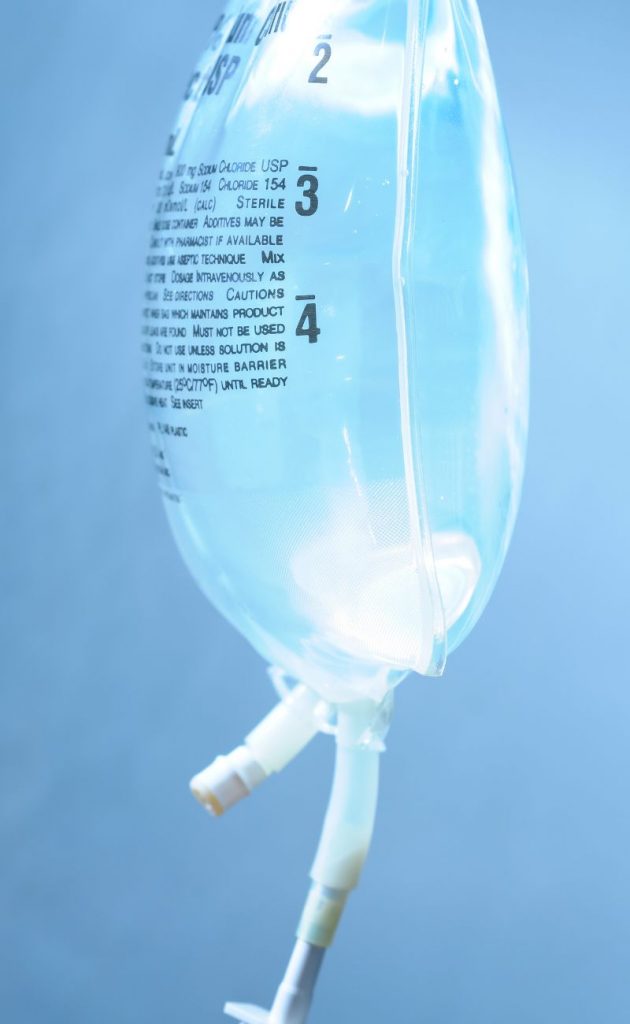

- Medicine - polyvinyl chloride is great for prosthetic limbs, hearing aids, but also for disposable items such as syringes and medical vessels.

- Household products - PVC is used to produce a lot of things needed in every home. We can mention, for example, coverings, mats, furniture fronts, children's toys.

- Special clothing - impact resistance makes PVC a component of protectors and helmets.

- Advertising - durable advertising signs and banners can also be produced from PVC.

Types of polyvinyl chloride

Two different types of PVC can be obtained from the polymerization of vinyl chloride. These are respectively: Unplasticized PVC and Plasticized PVC.

- Plasticized PVC is a raw material with an extremely flexible structure. Despite its considerable plasticity, it is resistant to impact and retains its consistency when stretched. At the same time, it is quite hard and has a high level of impact strength. Plasticized PVC exhibits flexibility and a lower melting point, which allows it to be processed at lower temperatures. Most commonly processed using injection molding, compression molding,

- Unplasticized PVC - a hard, inflexible and resistant polymer. It also exhibits complete inertness to oils and chemicals. It does an excellent job of insulating against fire, as it is a self-extinguishing material. Due to its higher melting point, unplasticized PVC is processed by thermal and mechanical methods. It can be easily cut, glued, but also welded.

PVC products from KK SOLUTIONS

We are experts in the field of plastic products. We offer both polymer processing machines and special production lines for manufacturing finished parts.

So take advantage of our experience and specialized staff of engineers to ensure your company's production success and high profit right now!